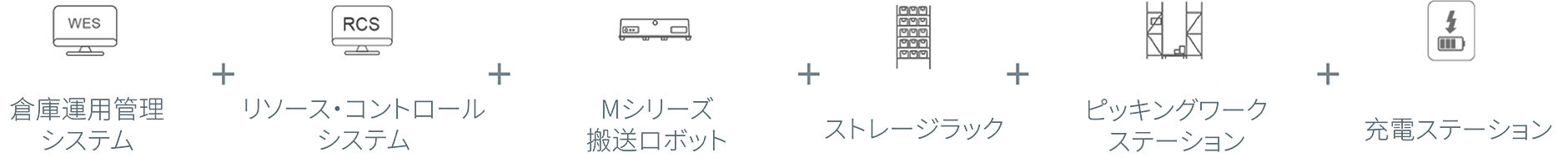

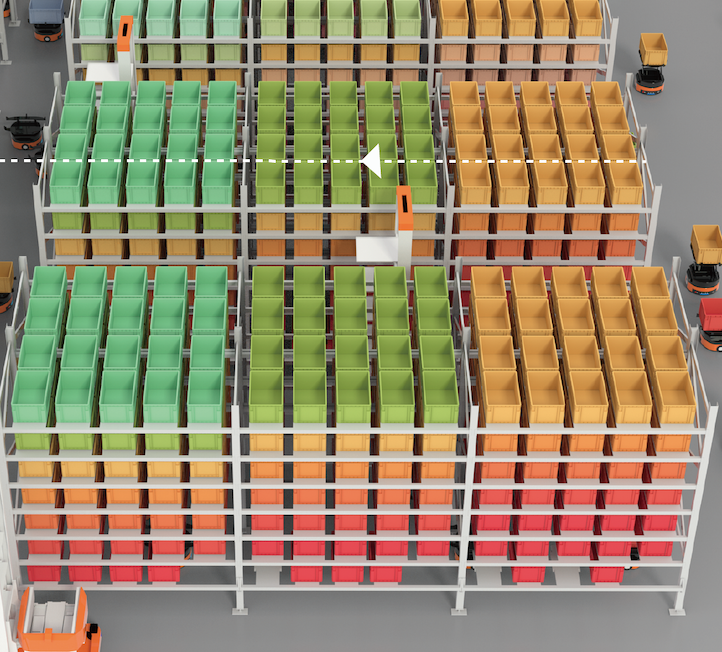

M型シリーズAGVによる搬送ハンドリング、可動棚、補充、ピッキング ワークステーション、WMS システム、RCS システムなどのハードウェアおよびソフトウェア システムで構成されます。 ワーカーのインテリジェントアルゴリズム ソフトウェア システムをコアとして、棚のピッキング、補充、返品など、倉庫内のすべての操作プロセスがワークステーションで完了します。

補充、棚卸、ピッキング、集中保管

Eコマース、3PL、スーパーマーケット

小売、衣料品、医薬品、美容、自動車部品、3C

効率が上がらない

人件費が高い

誤操作率が高い

注文がまとまらない

導入するための倉庫改造費用が高い

複数のアイテムの数量が少ない

搬送対象のサイズによるの制限がある

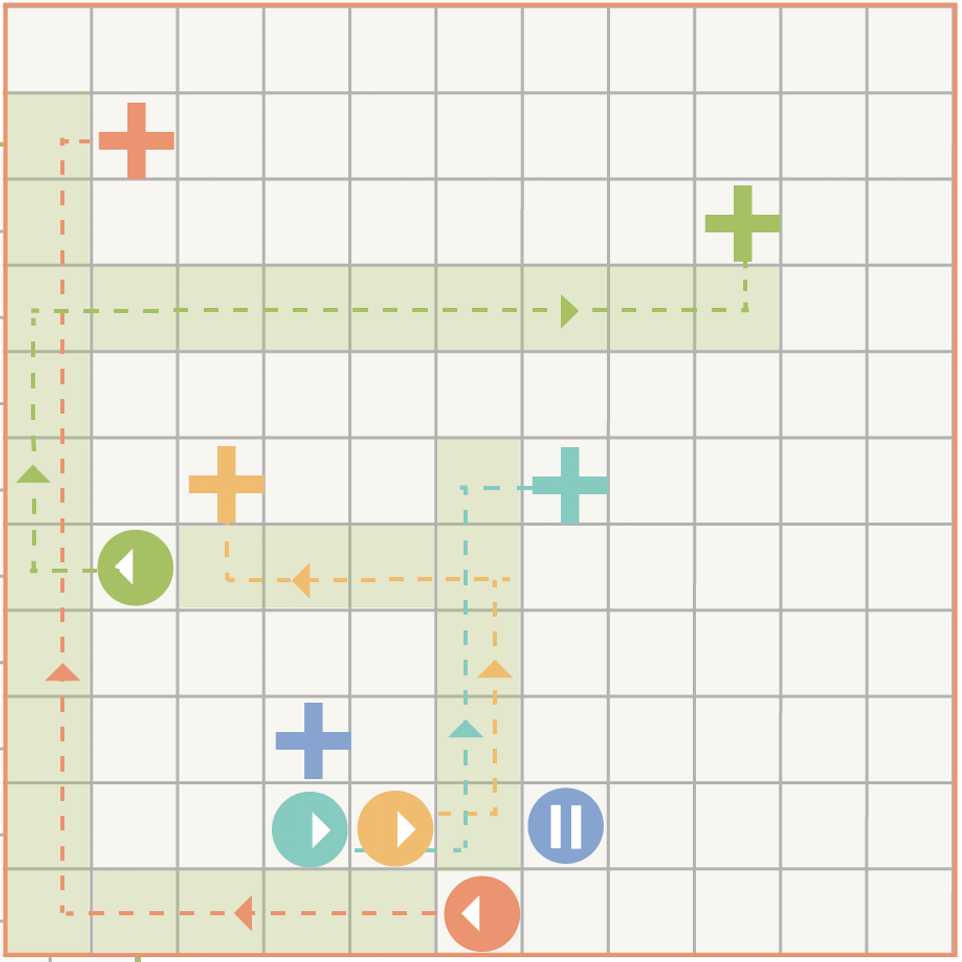

商品から人へのピッキングモード:ロボットがラックをピッキングステーションに移動し、ピッカーは移動する必要がありません

インテリジェントAIアルゴリズムは、大規模なロボットの運用に対応するために、ロボットの運転経路をリアルタイムで計画します

棚状況の分析と優先順位を調整します

ダイナミックなリソースの分配を実現

大量な発注の最適化を人工知能で実現

上流WMS等とのシームレスな接続が可能

プロジェクトの実装サイクルが短い

プロセス全体における手作業の削減

システムが自動的に作業をガイド

60%〜80%の労力削減

1~3年の投資回収期間

電子カタログ

YouTube公式チャンネル

TikTokアカウント