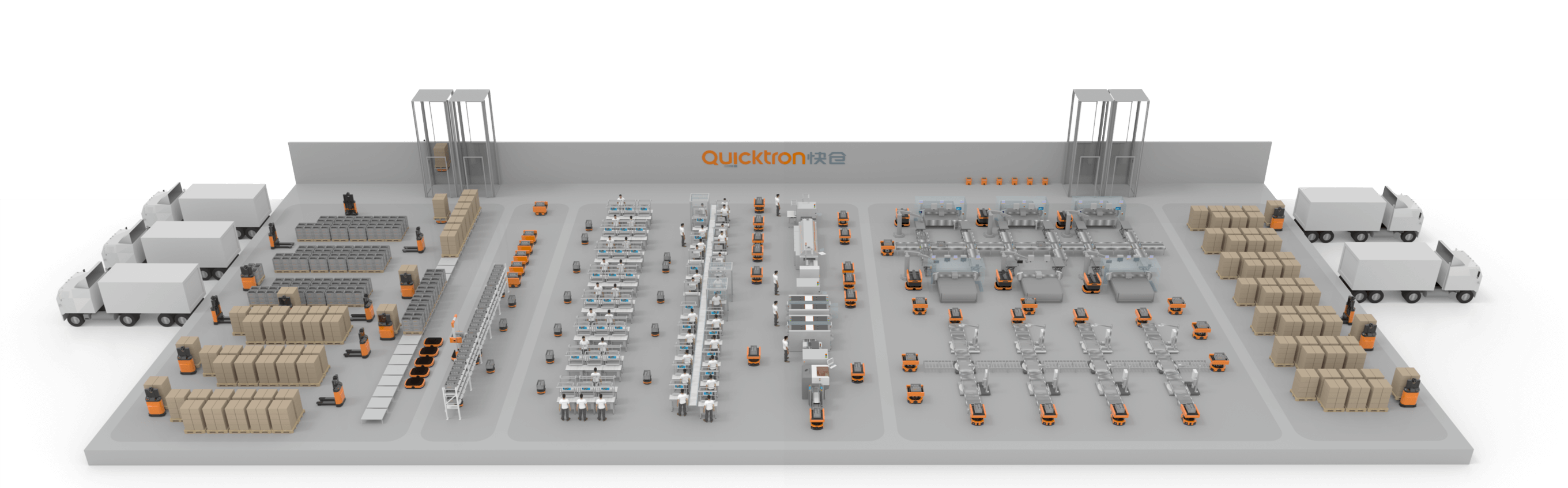

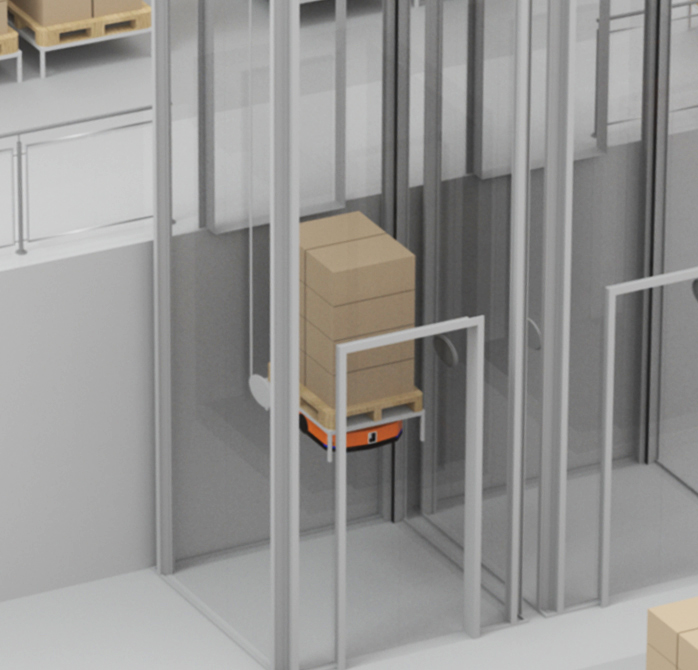

スマート搬送ソリューションスマート搬送ソリューションは、プラットフォームから保管エリア、保管エリアからピッキングおよび仕分けエリア、垂直倉庫のドッキング、ドッキングなど、生産プロセス全体でパレットやラックなどのマテリアルのスピーディーな伝達を実現できます。コンベアラインのドッキング、ロボットのドッキング、ホイストドッキング、エレベーター ドッキング、高速ドアドッキング、ピッキングおよび仕分けエリアからラインエッジ、ラインエッジから生産ライン機器、すべて柔軟な搬送を行います。

同時に、システムレベルは、上流システムの MES/ERP/WMS/SCADA システムに接続して、インテリジェントで柔軟な無人ソリューションを実現できます.ナビゲーション方法は、QRコードとSLAM方式をサポートし、シナリオに応じて異なるナビゲーション方式を使用したり、ハイブリッドナビゲーション方式を使用したりします。

ラインハンドリング、生産ライン設備で自動搬入出

スマートなハンドリング、柔軟性のある工程ライン

太陽光発電、リチウム電池、自動車(車両および部品)

PCB、電子機器製造、衣料品、食品

高い人件費、人材育成に時間かかる

リソースの無駄、材料は追跡不可

品質は保証されない、

サプライチェーンの

サイクルは長い

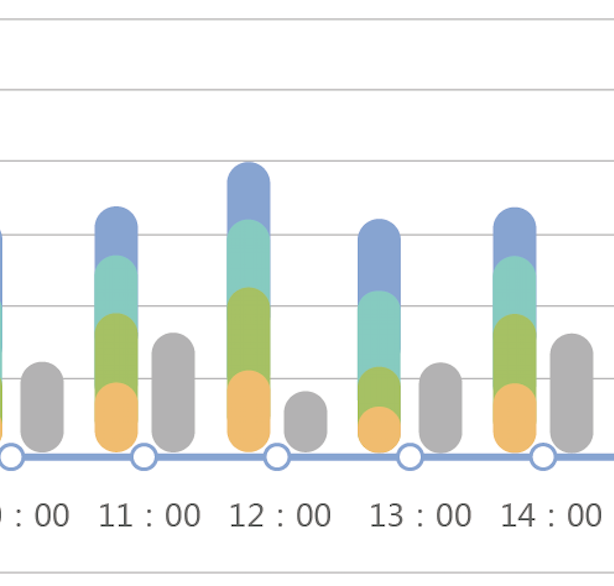

データのインプットとアウトプットが不一致

データの可視化ができない

上流と下流の連携が悪い 、 生産ライン

工程データが分断され

人員の供給、分配、および生産の混乱

人と設備の共同稼働により

生産リスクが生じる

社内情報システムが完備され、カスタマイズができる

全ての外部機器を監視するSCADAシステム付き

生産プルの自動化により、生産ラインの影響を受けなくなる

現場環境を変えることでインテリジェントな搬送を実現できる(2次元コード敷設、ビジュアルポジショニングコード貼り付け)

システム的な障害物回避

障害物回避のための複数のセンサー

高い柔軟性により、お客様が独自で機器の設置や

輸送ルートの変更を行うことができる

従来のソリューションにおけるフォークリフト

作業者への依存を解消

優れた経路計画能力

多様な機器ポートフォリオ力

保存率60%アップ

効率30%〜50%アップ

投資回収年数3年以内

電子カタログ

YouTube公式チャンネル

TikTokアカウント