In 2023 Let's Move the Future Smarter and Faster

Good companies follow the trend while Great companies aim to transform the world.

The energy crisis, the COVID-19 pandemic, the aging population, and several other calamities have affected 2022. However, during this turmoil, the long-term value of mobile robots has been acknowledged, applied, and continuously explored.

Quicktron is committed to moving the future of the intralogistics world with intelligent robotic technology.

Continuous emphasis on

Global Market Expansion and Investment

Behind the expansion of mobile robots in foreign markets, there is a strong determination of the company to penetrate global markets through a successful globalization strategy, and a superior systematic organizational capacity.

International sales have increased at a CAGR of over 300% in the last three years.

Global delivery became smoother and more efficient, and project acceptability enhanced by appr. 250%.

Overseas teams are rapidly expanding

Germany tech center is operational since last Novemeber

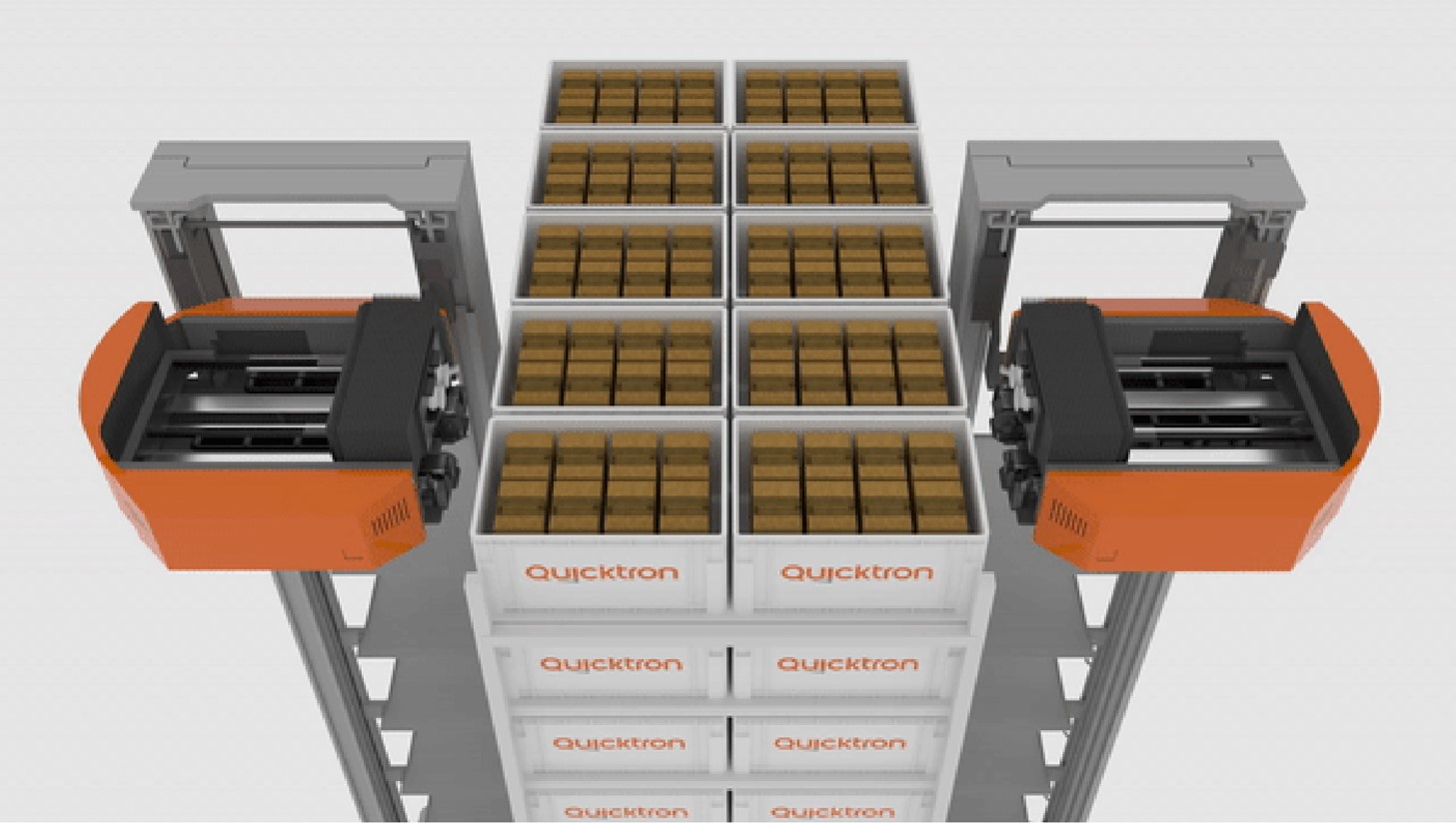

QuickBin is extremely popular in international markets. Cubyn, the first 3PL automated warehouse in France with 300+Units.

Winit is an international warehousing giant, that operates almost 200 warehouses in Germany.

Quicktron's flagship product QuickBin was showcased at LogiMAT, Germany's largest internal logistics expo, as well as the International Logistics Complex in Tokyo, Japan.

New Product Models &

Application Scenarios

Consumer demand is the strongest driving factor behind Quicktron's innovation. Only by addressing customers' critical issues and focusing on both current and future challenges can we develop suitable products.

World's first vacuum suction robots of this type, boosted the storage capacity by 71% and 20% reduction in shelf cost.

In China, Quicktron has developed the arm-type "LA300A" and the Cantilever type “LT30A” for the hot lithium battery market.

Smart Mobility

for Intralogistics

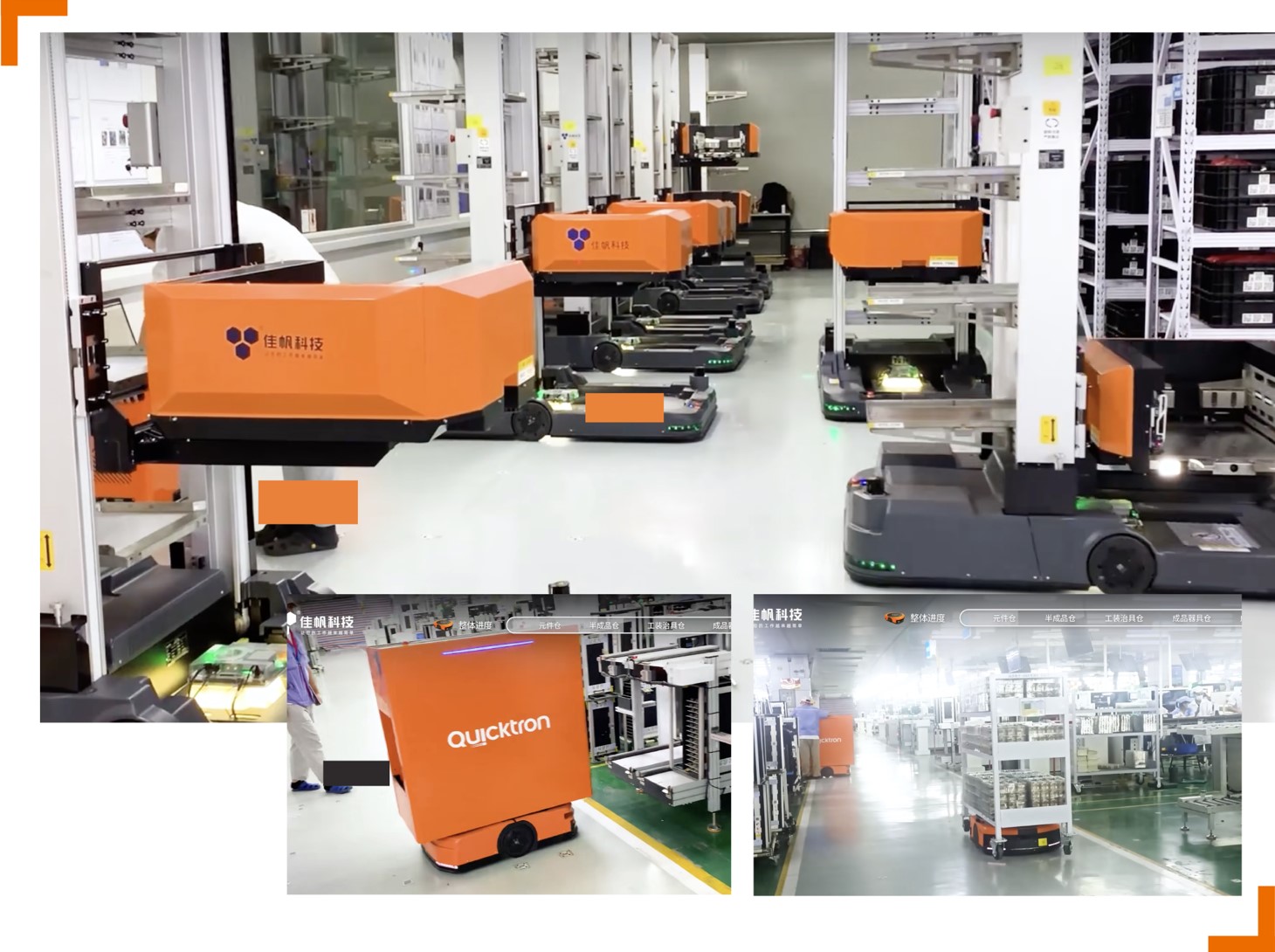

In the future, every smart warehouse and factory will have various types of robots running interactively, giving a look of a mini smart city inside the factory.

Quicktron's goal is to enable different types of robots to collaborate in a variety of scenarios. i.e., in a home appliance lighthouse factory, Quicktron has four types of robots, dealing with five application scenarios, with a clear division of labor and efficient collaboration.

With three generations of the smart operating system: each scenario can be iterated independently. Our partners can perform secondary development on the basis of the original system, which allows SLAM navigation and localization mode.

The Construction of

New Factory

to Boost Production

Quicktron's new factory is under construction which will constantly provide high-quality products to clients around the world in near future.

Quicktron's east China facility in Kunshan is fully operational and has a production capacity of 36,000 units per annum.

The factory's per capita production efficiency increased by approx. 140%.

Continuously improving production quality, customer satisfaction, and experience.