Modern automation technology has influenced almost every sector of the economy, but some sectors such as retail, e-commerce, 3PL, manufacturing, etc. have significant impacts. The public awareness of warehouse automation, and how it alters the way of warehouses to store, track, and transfer goods have increased as a result of this growth. What is warehouse automation? And why it's a necessity in today's era?

Warehouse automation is the process of automating the movement of inventory into, within, and out of warehouses to customers with minimal human assistance and higher efficiency. With warehouse automation, a company can get rid of labor-intensive tasks that require repeated physical labor, manual data input, and analysis. For instance, a warehouse employee/robot may put large products onto an AMR. Inventory is moved by the robot from one end of the warehouse to another, and the software tracks its progress to maintain all records up to date. These robots increase the task's effectiveness, precision, reliability, and speed.

Warehouse automation

is so crucial! Why?

The consumer experience suffers due to the inefficiency of warehouses. Automated warehouses can meet rising client demand while using fewer resources. Rising consumer expectations, timely delivery, order peaks, labor shortages, pandemics, safety concerns, smooth supply chain operations, multi and omnichannel fulfillment, return management, and similar challenges ignited the need of having an efficient automation solution. Companies are suffering due to the non-fulfillment of these problems which is why an increased automation trend has been predicted in several studies. A study explained that the use of warehouse automation is anticipated to reach 45% by 2030. Automation strives to minimize labor expenses, boost productivity and accuracy, and improve safety by making manual tasks less labor-intensive. Many warehouse automation solutions are available to expedite various warehouse operations. The important question is, which solution can best satisfy the needs of your industry? and what does Quicktron has to offer?

Quicktron's Intralogistics Solutions

We have the following intralogistics solutions which ease the warehousing needs of multiple industries and add value to the operations in several ways.

Good-to-person solutions

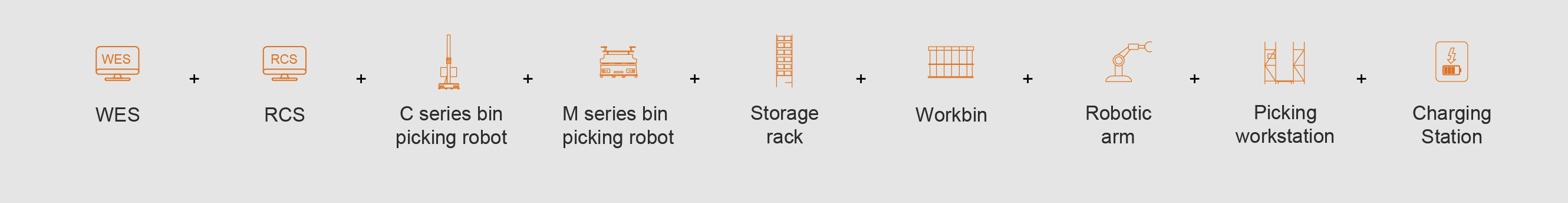

QuickBin is Quicktron's patented GTP bin-to-person solution that optimizes warehouse operations by utilizing two types of robots. The combination of the sturdy and efficient bin picker with the compact and agile bin mover enhances picking and bulk SKU handling efficiency. The collaborative work of these two robots is incredible, tall bin pickers retrieve bins from the storage area while small bin movers transport bins from the storage area to the picking area.

Value to customers

Quicktron has automated numerous domestic and international customer’s intralogistics processes with QuickBin solutions, including renowned brands such as Cubyn, Winit, Runbow, LF Logistics, and many more. With our innovative solution, the large number of SKUs picking and returns processing is smooth and unaffected by order volume spikes with improved efficiency (The operator can pick 400 order lines/hour, 3-4 times more efficiently than manual picking), optimized throughput (Up to 400 bins/hour in one aisle, and 6000 bins/hour in a single warehouse), flexible, and scalable system (fast installation with minimum disruptions to daily operations). The number of robots and workstations can be easily increased or decreased and customers can get massive ROI in just 1-2 years.

Shelf/Rack-to-person

Is a Goods-to-person (G2P) solution in which robots transfer, shelves, pallets, and racks to/from the workstations. These robots while moving to/from workstations, help increase picking efficiency for order fulfillment. Goods-to-person robots automate operations with massive SKUs and enhance processing efficiency.

This cost-effective solution is designed to eliminate non-value-added activity in the warehouse. Powered by proprietary algorithms, RCS, WMS systems, and CE-certified robots that meet rigorous safety requirements. When all of the elements are combined, the efficiency of picking, replenishment, returns processing, and other processes are increased by 2-3 times.

Value to the customers

Shelf/rack-to-person Smart picking has been a trustworthy solution to multiple warehousing challenges, especially in peak days, and many of our global customers from multiple industries such as Alibaba's logistic arm Cainiao, IQ fulfillment, Flash Express, Erke, Sinopharm, etc., etc. have automated their warehouses with our solutions and increased efficiency. It is efficient in full and split case picking, replenishment, put-away, and reverse logistics. Picking efficiency can be increased by 2-3 times with collision-free path planning, storage optimization, robot collaboration, and other algorithms to ensure fast delivery of goods to the operator. Multiple orders can be fulfilled simultaneously. Flexible operation with a seamless connection with OMS/WMS/MES upper-level systems shortens the implementation period. While labor costs are reduced by 60-80%, solving the issue of hiring temporary workers for peak seasons. Decrease the number of returns that occurred due to picking errors with 99.99% accuracy and quick ROI in 1-3 years.

Point-to-Point

Smart Moving Solutions

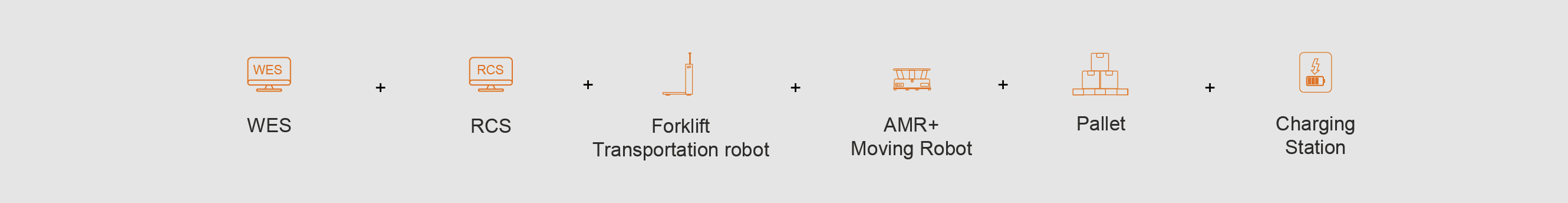

Quicktron point-to-point robotic solutions are designed to transfer goods, and dock with other equipment on the factory floor and in the warehouse, with or without human interaction. Point-to-point robots perform tasks like transfer and lifting as well as moving pallets, goods, parts, and half-finished products.

AMR+ series robots are enhanced with belts, double roller conveyors, robotic arms, and other mechanisms based on the client’s specific needs for production. To meet the needs of various industrial scenarios, QR code, SLAM, or hybrid navigation technology is used in robots to assure smooth mobility.

Value to the customers

Our Smart moving P2P solution made transportation to the assembly line easier, with automated loading, and unloading, point-to-point delivery, and a flexible production line that added value to the customer’s warehousing and material handling operation and realized the unmanned operations. It’s a safe, reliable solution because obstacle avoidance is executed by the system and through multiple robot sensors. Flexible deployment with which customers can add robots and modify transportation routes independently. A significant increase in efficiency by 3-4 times, an 80% increase in storage capacity, and at the same time labor costs can be reduced by 40-60%, solving the reliance on the traditional forklift in industrial applications. We have a list of satisfied customers worldwide including Mitsubishi Elevators, Mercedes Benz, Loreal Paris, etc, and this list is unending.

Benefits of

Warehouse automation

The benefits of warehouse automation are multi-fold. The important one is that it sets the human free from tedious repetitive manual tasks and reduces manual errors. The modern-day fulfillment challenges are easy to handle. From running more efficiently to minimizing human error here's a summary of the most commonly cited advantages:

Hence, automation is one of the best ways to improve logistics efficiency. Deploying autonomous mobile robot technology in your business offers several benefits, including increased productivity, greater safety in product management, and more agility in storage and order-picking operations.

We at Quicktron have extensive expertise in creating and deploying intralogistics solutions for businesses across many industries. Interested in taking advantage of the benefits of automating your logistics processes? Contact us so we can demonstrate how our automated solutions can help your company succeed.