|

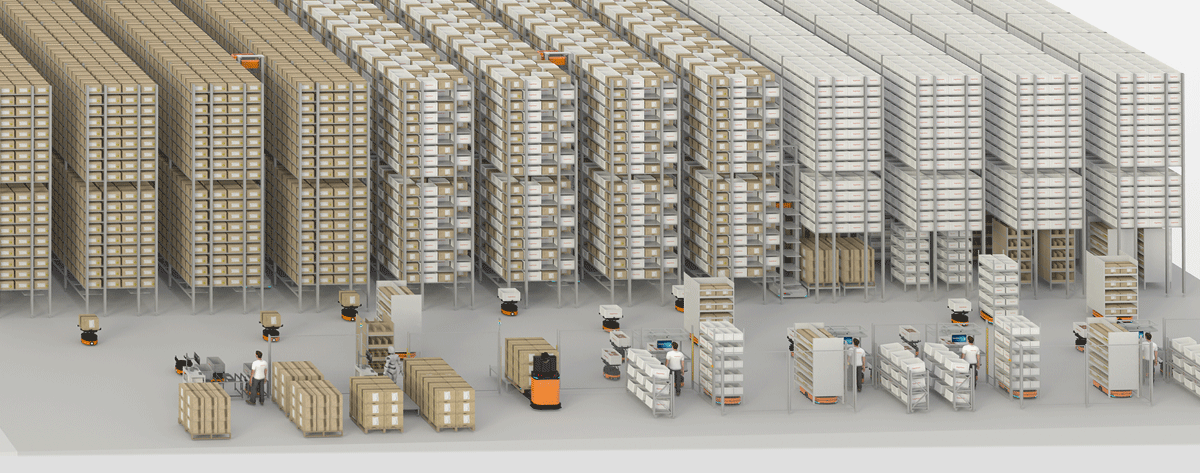

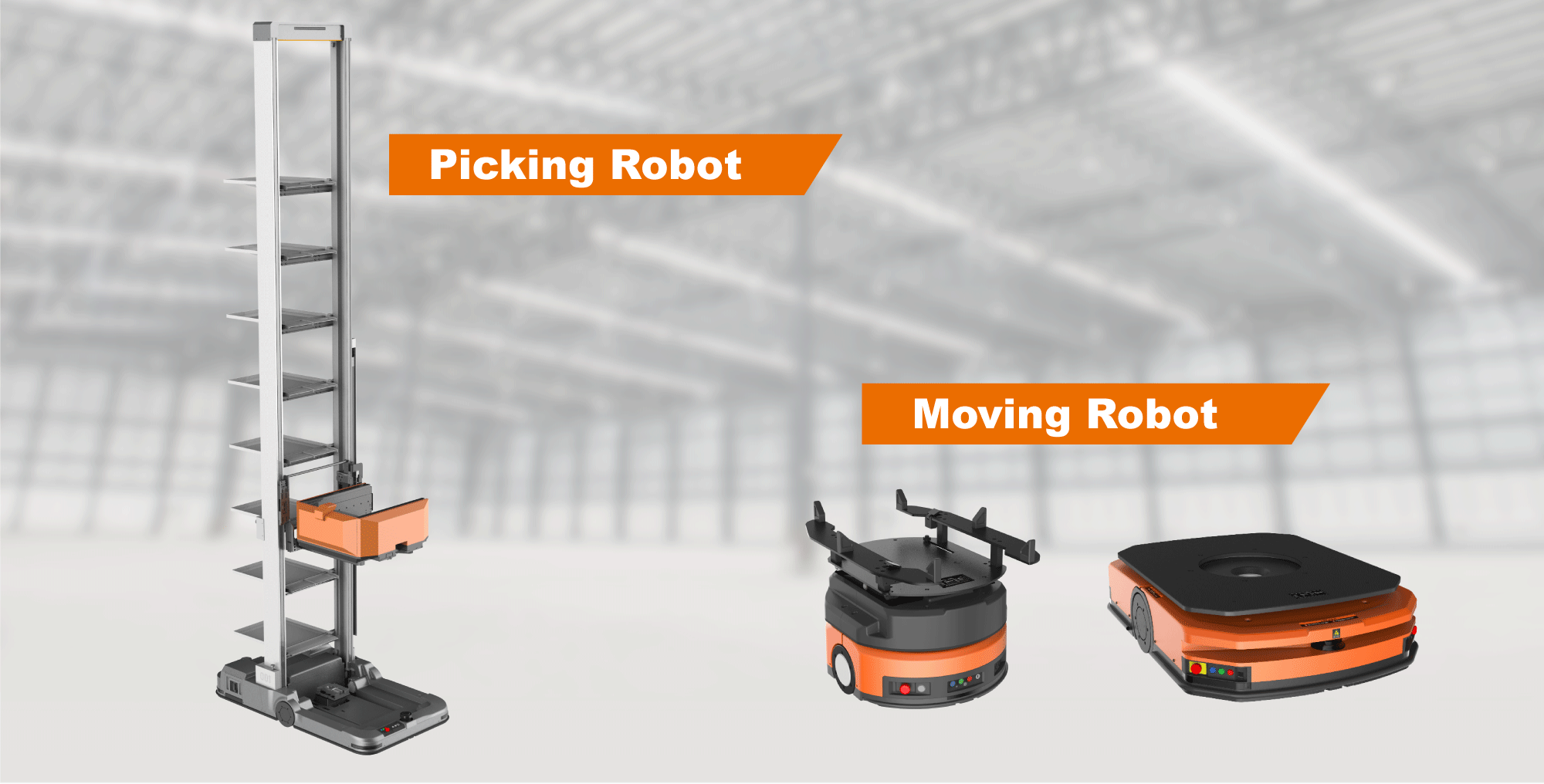

This prototype is an all-in-one GTP solution that works with the collaboration of picking and two types of moving robots. Picking robots to perform storage and retrieval and move within the aisles in the storage area while moving robots transfer bins/racks to or from workstations. This unique prototype offers plenty of options to store, move and pick goods. You can choose one-stop storage with centralized picking and increase the delivery speed with higher throughput and scalability. |

|

|

|

|

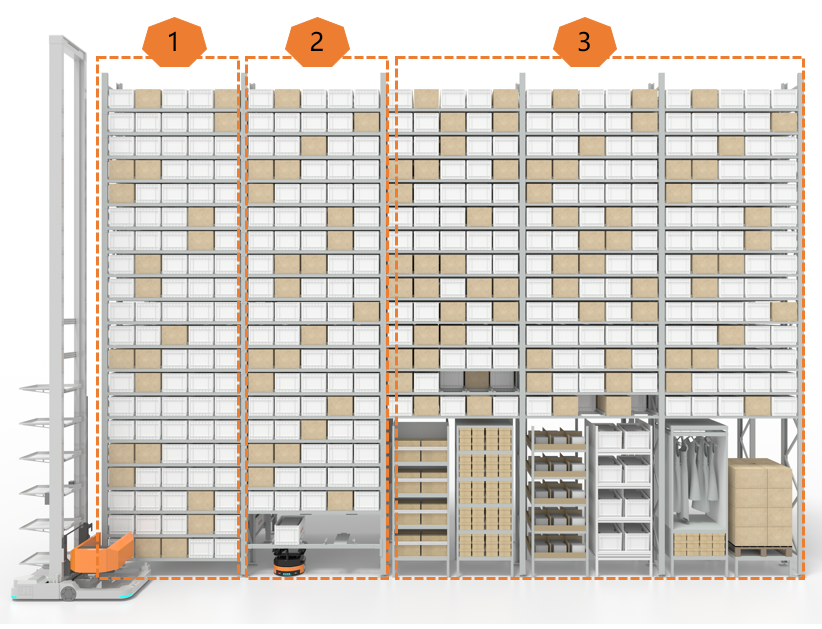

1: For scenarios with lower traffic and significant storage requirements such as the back end of a large warehouse, QB higher storage is preferred. 2: For scenarios with high traffic requirements, keep the bottommost portion of storage space vacant for the temporary storage of goods which enhances the traffic flow. 3: For the unsuited oversized bins, the shelf mode in the lower portion can be adopted which increases the size range of SKUs Storage (clothing hanging). 3: For sorting scenarios, sort the goods by picking from the upper portion and then placing them on a shelf/rack in advance, this is how multiple SKUs that need to be sorted are organized on the shelf and moved at once, efficiently solving the sorting problem (Same type items of the store). |

|